LAVA pumice stone stands as a naturally occurring, chemically inert building material boasting an array of exceptional traits. Its distinctive characteristics have been harnessed by various industries across the US, Europe, Middle East, and Greece for many years. These industries have leveraged its unique properties to craft high-quality building materials, aligning perfectly with global regulations and modern construction demands.

Pumice qualities are suitable for building material applications including:

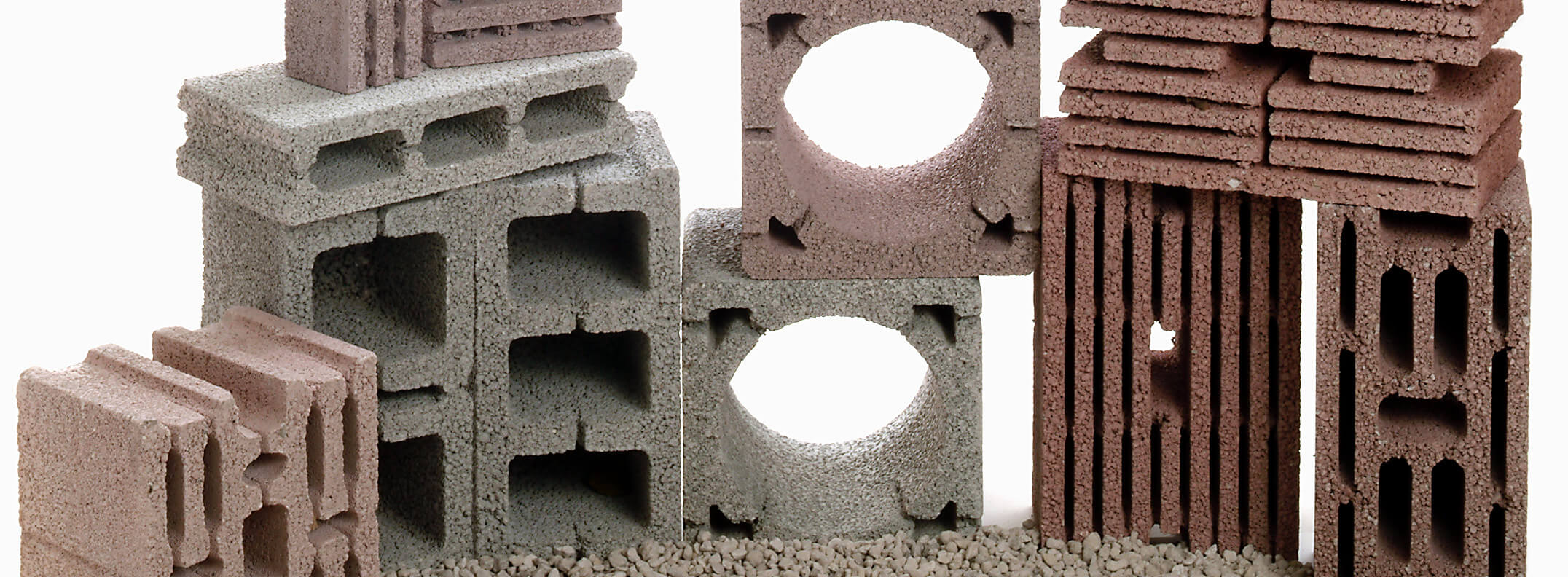

- Lightweight structural precast members (pumice concrete blocks)

- Structural lightweight concrete

- Non-structural lightweight concrete (insulation and floor fillings)

- Lightweight shotcrete

- Pozzolanic material in Cement industry

- Excellent mechanical strength-to-weight ratio. High strength values are achieved with approx. 30% lower weight than standard concrete, which is extremely beneficial for the structure’s cost-efficiency and behaviour (reduced dead loads and transportation costs).

- They are used for all types of lightweight concrete:

- Structural: Compressive strength > 15 Mpa, Density < 2000 Kg/m3

- Structural and thermal-insulating: Compressive strength > 3.5 Mpa, Density < 1400 Kg/m3

- Thermal-insulating: Compressive strength 0,5 Mpa, Density < 1000 Kg/m3

- They are used for the production of pumice concrete blocks as building material for non-bearing masonry:

- Compressive strength: 2.5-10 Mpa

- Material density: 900-1400 Kg/m3

- High thermal-insulating capacity

- Thermal conductivity λ=0,22-0,33W/mK

- Excellent sound-dampening properties thanks to the pumice stone’s porous texture that traps air, and high soundproofing-to-weight ratio

- They are non-combustible, thus enhancing the structure’s fire resistance

- They feature good seismic behaviour